GAC R&D Center

Founded in 2006, GAC R&D CENTER is the technology management department and R&D system hub of GAC GROUP. Its core responsibilities include independent product development, the formulation and implementation of independent technology plans, and the overall planning of GAC GROUP's technology management.

Supported by R&D centers in America and GAC Advanced Design Shanghai, a Guangzhou headquarters-centered GAC global R&D network, which pools together leading suppliers and R&D institutions across the globe, has been set up.

GAC R&D CENTER has world-leading R&D facilities, including 15 types of labs involving vehicle, powertrain, new energy, Intelligent Connected Vehicle (ICV), a trial production factory with welding, painting, final assembly, and machining that produces 800 sample vehicles a year, and a special track for car tuning.

Investment And Talents

A total of more than 30 billion yuan have been invested in independent research and development. Of the 4300 + employees of the GAC R&D CENTER, 92% hold a bachelor’s or higher degree, and 110 a PhD degree. Led by a top team of experts who are also outstanding talents in science and technology from China's automotive industry, or leading talents introduced by Guangdong province, an international R&D team with leading independent R&D efficiency has been set up. Members of the team come from a dozen of countries including Germany, Italy, the United States, Japan, South Korea, etc.

Wu Jian

Wu JianPresident of GAC R&D Center

Head of Powertrain

Technology Center Zhang Fan

Zhang FanVice President

of GAC R&D CenterHead of Design Center

Marco Gilardi

Marco GilardiCTO of GAC R&D Center

Expert of Chassis Tuning

Pontus Fontaeus

Pontus FontaeusTechnical Director

of GAC R&D CenterHead of GAC Advanced Design Center Los Angeles

GAC R&D CENTER engages in industry-university-research cooperation with prestigious universities and research institutions at home and abroad, such as Tsinghua University, Jilin University, South China University of Technology, Hunan University, Central Academy of Fine Arts, Art Center College of Design, China Automotive Technology & Research Center Co., Ltd., China Automotive Engineering Research Institute Co. Ltd, etc. With dozens of ongoing projects, the Center attracts talents and innovation resources from around the world.

Production System

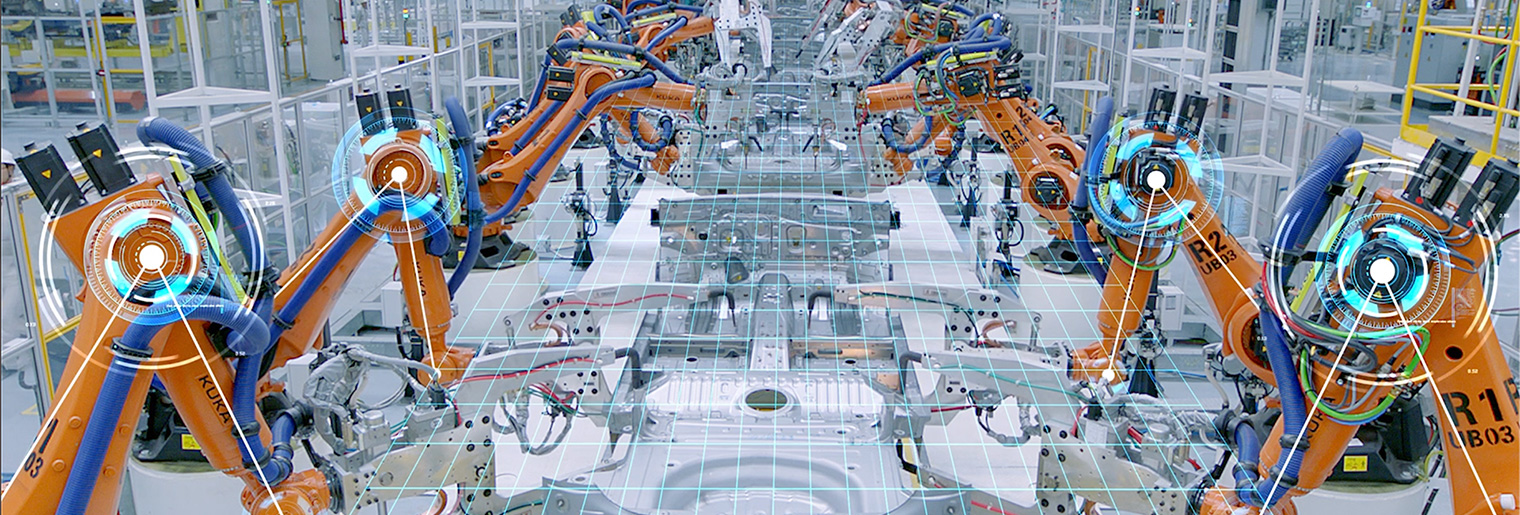

Consisting of the world-class 6-bar servo presses and 8-bar mechanical presses as well as rotating 7-axle AGVs and straight 7-axle AGVs, the two automatic production lines ensure high-quality and high-precision Pressing of complex workpieces.

The welding workshop comprises five main production lines, i.e. floor assembly, auto body assembly, body side assembly, assembling and 4 doors and 2 covers. It adopts the world-class NC-locator, CNCservo rapid rolling technology, and Robot team technology (multi-robot cooperation technology). These diversified, flexible and small-batch production lines provide five-star safety guarantee for GAC MOTOR production, down to every minute detail.

The painting workshop encompasses the processes of pretreatment electrophoresis, sealant, floating coat, setting paint and inspection process, using safe and environmentally friendly water-based paint. Advanced 16-section rectification technology is adopted for the electrophoresis process, which guarantees that vehicles meet the 10-year corrosion prevention standard. In addition, robot spray painting is employed for the internal plates, which improves spraying efficiency by 15%, realizes 10% energy conservation and reduces VOC emission by approximately 13%.

Consisting of motor and gearbox production line, GAC MOTOR powertrain plant organizes production according to vehicle order, with BEOL (the back-end-of-line) driving FEOL (the front-end-of-line). The powertrain plant adopts the world most advanced, high-precision production facility and rigorous inspection standards, all for the sake of ensuring that each motor that comes off the line is well-built with premium quality.

Through 5 static mandatory testing and side-slip measurements, i.e. four-wheel aligner, headlamp aligner, chassis dynamometer, braking force test stand and vehicle lamp testing, the vehicle testing line guarantees the function and safety of every vehicle before delivery.

The main conveying lines adopt a four-fold-line five-function process layout that allows maximum use of space. World-class equipment is utilized for key processes, which, combined with GAC MOTOR unique production mode, enables multiple models to be produced on the same line and with internationally top-notch quality.

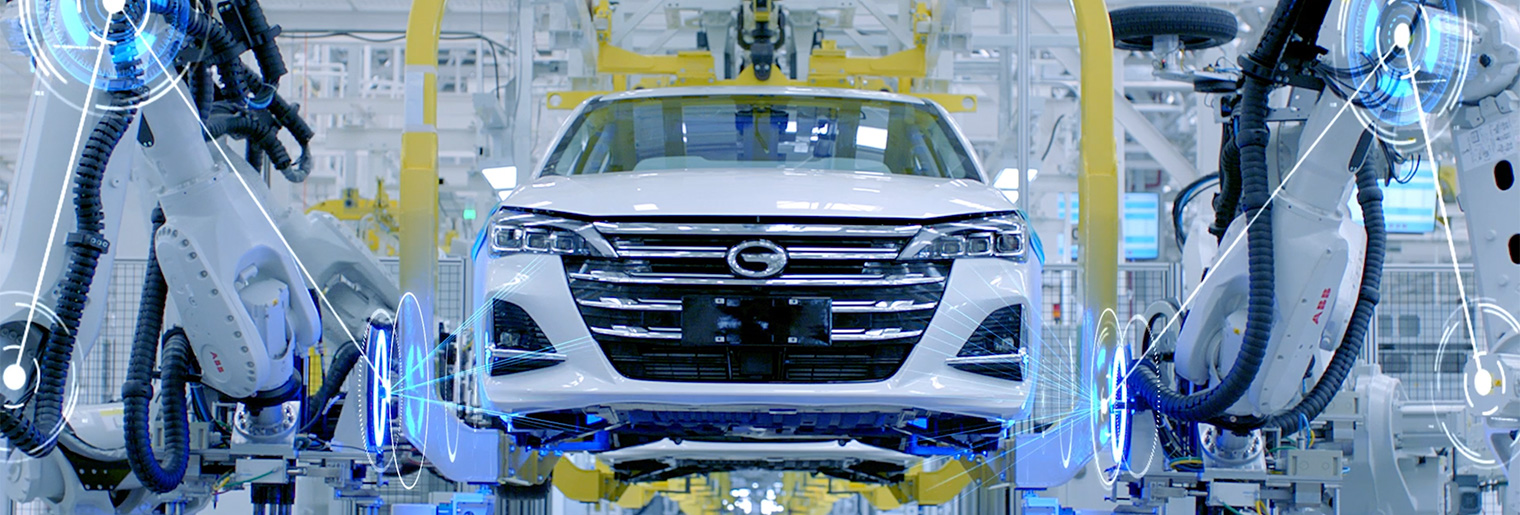

GAC MOTOR Plant

Built according to world-class industry standards, the GAC MOTOR plant is a high-efficiency, high-quality, energy-saving and environment-friendly world-class model plant of intelligent manufacturing that realizes the organic integration of production automation, information digitalization, intelligent management and ecological intelligent manufacturing.

QC System

GAC MOTOR has created a quality management mode with "Stop-Call-Wait and PDCA" as the core flows, "standardization, systematism and platform" as the basis and "basic concept of quality control, quality assurance in process and constant improvement" as three vital elements, so as to ensure the cross-year, cross-platform and cross-model quality consistency in the quality system of GAC MOTOR. In order to ensure high quality and high safety, GAC MOTOR established a strict "6520" quality control system, carrying out "6 characteristic activities", taking the "5 monitorings" and "2 Screenings" as the main measures to achieve the "zero defect" goal, so as to fully improve product quality and provide consumers with high-quality and cost-effective products.